BENCHTOP MACHINES

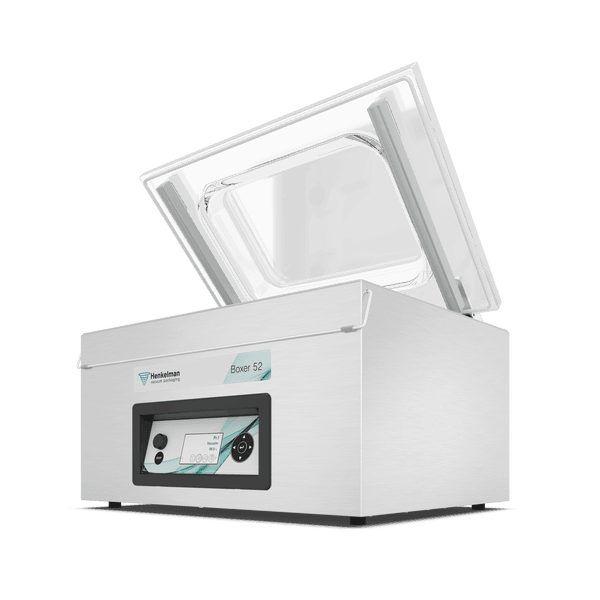

Boxer 52

The robust stainless steel Boxer 52 II vacuum packaging machine comes standard equipped with two seal bars, a Busch vacuum pump, and Digital control with a 10-program memory. This tabletop model complies with CE standards.

- Features

- Dimensions

- Options

- Accessories

- Table model

- Stainless steel housing

- Stainless steel deep-drawn vacuum chamber for optimal hygiene

- Transparent lid

- Easily removable wireless sealing bars in vacuum chamber

- Insert plates for adjusting vacuum chamber height

Packaging functions

- Vacuum

Optimal final vacuum 99,80% (2 Mbar) - Gas-flush

Injecting food-gas for product protection and longer shelf life - Soft-air

Controlled ventilation for protection of product and packaging

Sealing systems

- Double Seal

2 x 3,5 mm convex sealing wires for product remains

elimination and strong hermetic seals. - Cut-off seal

1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round

cutting wire / One time setting (cut off remaining flap) - 1-2 Cut-off seal

1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round

cutting wire / Independent time setting (shrink bags) - Wide Seal

1 x 8.0 mm flat sealing wire

Digital control functions

- Time Control

Time control / Automatic programming / 10 default programs - Sensor Control

Set percentage pressure for vacuum and gas

functions for accurate and constant packaging results /

Automatic programming / 10 default programs /

Vacuum plus time - Quick stop H2O Sensor Control

Set percentage pressure for vacuum and detect boiling point of the product. For fast cycle and better food protection

Support control functions

- STOP button for partial/full cycle interruption

- Digital maintenance program for pump / Operating hours counter / Service indicator programs / Sleeper function etc. Optional functions / Accessories

- Inclined insert plate for packaging liquid products

- Connector for external vacuuming of food containers

- Service kit for standard maintenance

- Special machine adaptations for specific products and/or production environments

- Trolley with shelves and castors

See more

- Features

- Dimensions

- Options

- Accessories

- Table model

- Stainless steel housing

- Stainless steel deep-drawn vacuum chamber for optimal hygiene

- Transparent lid

- Easily removable wireless sealing bars in vacuum chamber

- Insert plates for adjusting vacuum chamber height

Packaging functions

- Vacuum

Optimal final vacuum 99,80% (2 Mbar) - Gas-flush

Injecting food-gas for product protection and longer shelf life - Soft-air

Controlled ventilation for protection of product and packaging

Sealing systems

- Double Seal

2 x 3,5 mm convex sealing wires for product remains

elimination and strong hermetic seals. - Cut-off seal

1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round

cutting wire / One time setting (cut off remaining flap) - 1-2 Cut-off seal

1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round

cutting wire / Independent time setting (shrink bags) - Wide Seal

1 x 8.0 mm flat sealing wire

Digital control functions

- Time Control

Time control / Automatic programming / 10 default programs - Sensor Control

Set percentage pressure for vacuum and gas

functions for accurate and constant packaging results /

Automatic programming / 10 default programs /

Vacuum plus time - Quick stop H2O Sensor Control

Set percentage pressure for vacuum and detect boiling point of the product. For fast cycle and better food protection

Support control functions

- STOP button for partial/full cycle interruption

- Digital maintenance program for pump / Operating hours counter / Service indicator programs / Sleeper function etc. Optional functions / Accessories

- Inclined insert plate for packaging liquid products

- Connector for external vacuuming of food containers

- Service kit for standard maintenance

- Special machine adaptations for specific products and/or production environments

- Trolley with shelves and castors

See more

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec quis massa condimentum, viverra tortor nec, sagittis neque. Nunc pharetra efficitur nibh, a pretium nibh viverra vitae.

Peter White

Store manager