Polar 2-50

- Features

- Dimensions

- Options

- Accessories

Specifications:

- Capacity pump 100 m3/h

- Machine cycle 15-40 sec.

- Dimensions 1545 x 900 x 1175 mm

- Voltage 400V-3-50Hz(Other voltages available)

- Power 3.5 – 5.3 KW

GENERAL

- Renowned series of stainless steel packaging machines for industrial applications

- Full range for vacuum and MAP packaging options

- Extensive program choices for specific packaging requirements

- Extremely large variety of applications in worldwide industrial productions

- User friendly and low maintenance, supplied with complete service program

- Well-balanced constructions and high quality materials guarantee durability

Packaging Functions

- Vacuum – Optimal final vacuum 99.99% (0,1 Mbar)

- Soft-air – Controlled ventilation for protection of product and packaging (optional)

- Gas-flush – Injecting food-gas for product protection and longer shelf life (optional)

Sealing Systems

- Double Seal – 2 x 3.5 mm convex sealing wire for optimal moisture elimination (double protection)

- Trennseal – 1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round cutting wire / One time setting (cut off remaining flap) (optional)

- 1-2 Trennseal – 1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round cutting wire / Independent time setting (shrink bags) (optional)

- Wide Seal – 1 x 8.0 mm flat sealing wire (optional)

- Bi-Active Seal – Upper and lower sealing bars with 1 x 5.0 mm flat sealing wire (thick and aluminium vacuum bags) (optional)

Operational Control Functions

- Digital Control – Time control / Automatic programming / 10 default programs

- Sensor Control – Set percentage pressure for vacuum and gas functions for accurate and constant packaging results / Automatic programming / 10 default programs / Vacuum plus time (optional)

Support Control Functions

- STOP button for partial/full cycle interruption

- Digital maintenance program for pump / Operating hours counter / Service indicator programs / Sleeper function etc.

- Chamber dimensions (L x W x H): 500 x 620 x 240 mm

- Machine dimensions (L x W x H): 920 x 1480 x 1325 mm

- Seal bars (L): 2 x 620 mm

Food Products:

Industrial Production – Wholesale – Export Packaging (meat, poultry, fish, cheese, vegetables etc.)

- Longer shelf life / Optimal product and storage hygiene (no contamination, hermetically sealed)

- No loss of product (prevents drying out, moulds and freeze burn)

- Improved product quality (product maturing in packaging, no loss of aroma)

- Cost savings due to longer shelf life (larger purchasing amounts, re-packaging)

- Increased turnover due to longer shelf life (broader market, more variation in product range)

- Professional product presentation

- Optimal packaging contributes to food safety and HACCP standards

Non-Food Products:

Electronics – Semi-conductors – Metal – Pharmaceutical Products – Textiles – Laboratories etc.

- Moisture free anti-corrosive packaging

- Air and dust-free antistatic packaging

- Volume reducing packaging

- Product protecting and fraud resistant packaging

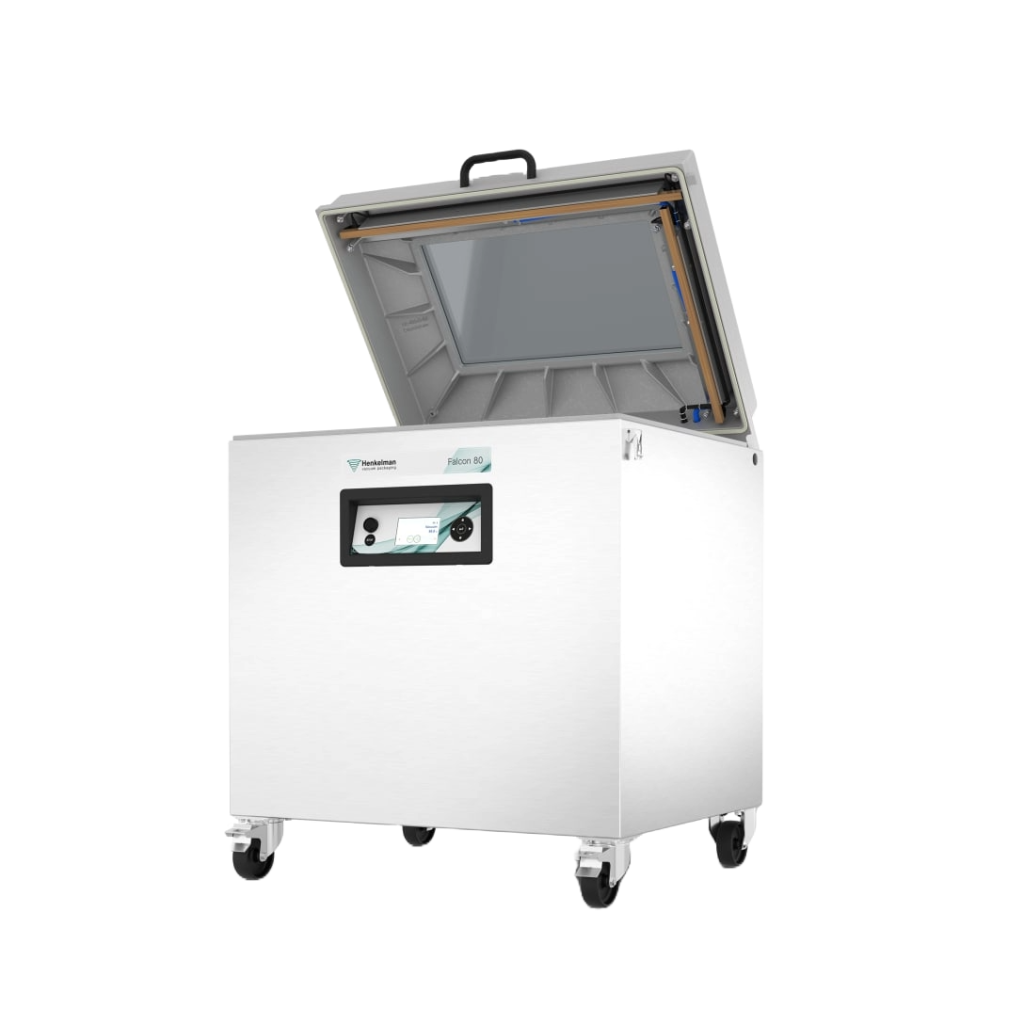

SPECIFICATIONS

- Single and double chamber floor models

- Stainless steel housing

- Stainless steel flat working plate

- Stainless steel lid

- Easily removable silicon holders for cleaning working plate

- Sealing mechanism mounted in lid

- Insert plates for adjusting vacuum chamber height

Optional Functions / Accessories

- Service kit for standard maintenance

- Special control options for specific applications

- Special machine adaptations for specific products and/or production environments

- Features

- Dimensions

- Options

- Accessories

Specifications:

- Capacity pump 100 m3/h

- Machine cycle 15-40 sec.

- Dimensions 1545 x 900 x 1175 mm

- Voltage 400V-3-50Hz(Other voltages available)

- Power 3.5 – 5.3 KW

GENERAL

- Renowned series of stainless steel packaging machines for industrial applications

- Full range for vacuum and MAP packaging options

- Extensive program choices for specific packaging requirements

- Extremely large variety of applications in worldwide industrial productions

- User friendly and low maintenance, supplied with complete service program

- Well-balanced constructions and high quality materials guarantee durability

Packaging Functions

- Vacuum – Optimal final vacuum 99.99% (0,1 Mbar)

- Soft-air – Controlled ventilation for protection of product and packaging (optional)

- Gas-flush – Injecting food-gas for product protection and longer shelf life (optional)

Sealing Systems

- Double Seal – 2 x 3.5 mm convex sealing wire for optimal moisture elimination (double protection)

- Trennseal – 1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round cutting wire / One time setting (cut off remaining flap) (optional)

- 1-2 Trennseal – 1 x 3.5 mm convex sealing wire + 1 x 1.1 mm round cutting wire / Independent time setting (shrink bags) (optional)

- Wide Seal – 1 x 8.0 mm flat sealing wire (optional)

- Bi-Active Seal – Upper and lower sealing bars with 1 x 5.0 mm flat sealing wire (thick and aluminium vacuum bags) (optional)

Operational Control Functions

- Digital Control – Time control / Automatic programming / 10 default programs

- Sensor Control – Set percentage pressure for vacuum and gas functions for accurate and constant packaging results / Automatic programming / 10 default programs / Vacuum plus time (optional)

Support Control Functions

- STOP button for partial/full cycle interruption

- Digital maintenance program for pump / Operating hours counter / Service indicator programs / Sleeper function etc.

- Chamber dimensions (L x W x H): 500 x 620 x 240 mm

- Machine dimensions (L x W x H): 920 x 1480 x 1325 mm

- Seal bars (L): 2 x 620 mm

Food Products:

Industrial Production – Wholesale – Export Packaging (meat, poultry, fish, cheese, vegetables etc.)

- Longer shelf life / Optimal product and storage hygiene (no contamination, hermetically sealed)

- No loss of product (prevents drying out, moulds and freeze burn)

- Improved product quality (product maturing in packaging, no loss of aroma)

- Cost savings due to longer shelf life (larger purchasing amounts, re-packaging)

- Increased turnover due to longer shelf life (broader market, more variation in product range)

- Professional product presentation

- Optimal packaging contributes to food safety and HACCP standards

Non-Food Products:

Electronics – Semi-conductors – Metal – Pharmaceutical Products – Textiles – Laboratories etc.

- Moisture free anti-corrosive packaging

- Air and dust-free antistatic packaging

- Volume reducing packaging

- Product protecting and fraud resistant packaging

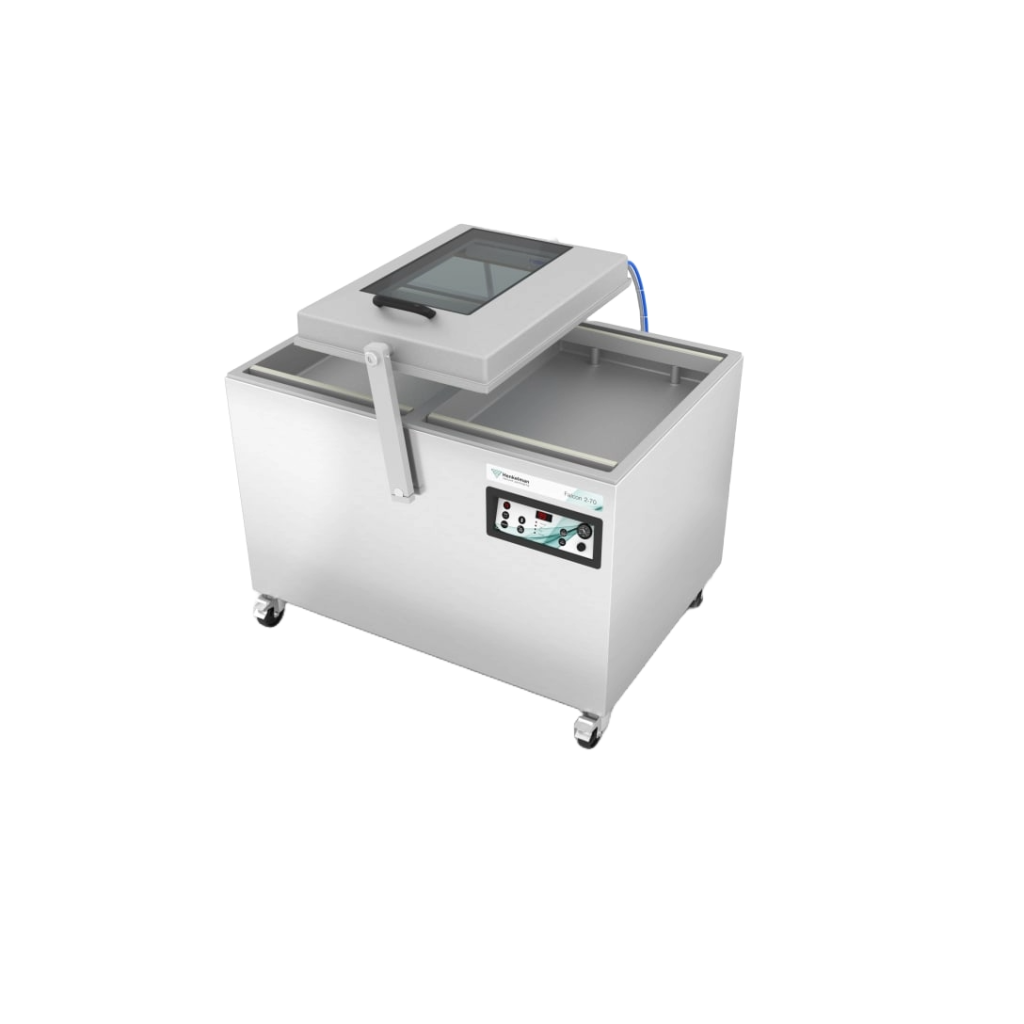

SPECIFICATIONS

- Single and double chamber floor models

- Stainless steel housing

- Stainless steel flat working plate

- Stainless steel lid

- Easily removable silicon holders for cleaning working plate

- Sealing mechanism mounted in lid

- Insert plates for adjusting vacuum chamber height

Optional Functions / Accessories

- Service kit for standard maintenance

- Special control options for specific applications

- Special machine adaptations for specific products and/or production environments

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Donec quis massa condimentum, viverra tortor nec, sagittis neque. Nunc pharetra efficitur nibh, a pretium nibh viverra vitae.

Peter White

Store manager